Corrosion Resistant Service & Insulated Doors

Insulated DoorsModel Number: ESD10CR(Service) & ESD20CR(Insulated)

Overhead Rolling Doors for Corrosive Environments

Our rolling and insulated doors have been redesigned to meet the heavy-duty needs of water treatment plants and other high-corrosive environments. Our durable Corrosion Resistant Service and Insulated Doors reinforce your building’s structural integrity, reduce repair costs, and protect your equipment.

The standard operator for Corrosion Resistant Service and Insulated doors is a NEMA 4X that delivers dependability and is built to last cycle through cycle. Curtain and guides are available in 304SS or clear anodized finishes. Also available in stainless steel, the corrosion resistant door is made to withstand a static windload of 40SPF.

Other standard features include corrosion resistant fasteners, a stainless steel headplate, zinc coated bearing, a ZRG powder coated shaft, and stamped stainless steel endlock/windlock.

Each of these features ensures a safe, long-lasting design for water treatment plants, chemical storage facilities and any other harsh corrosive environment.

Technical Data Sheets

Specification Sheets

Drawing Generator

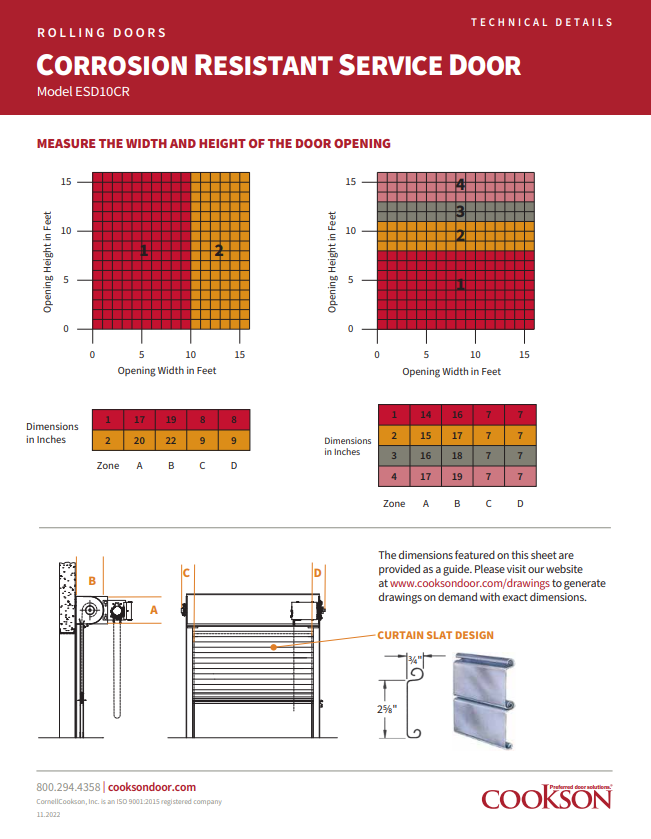

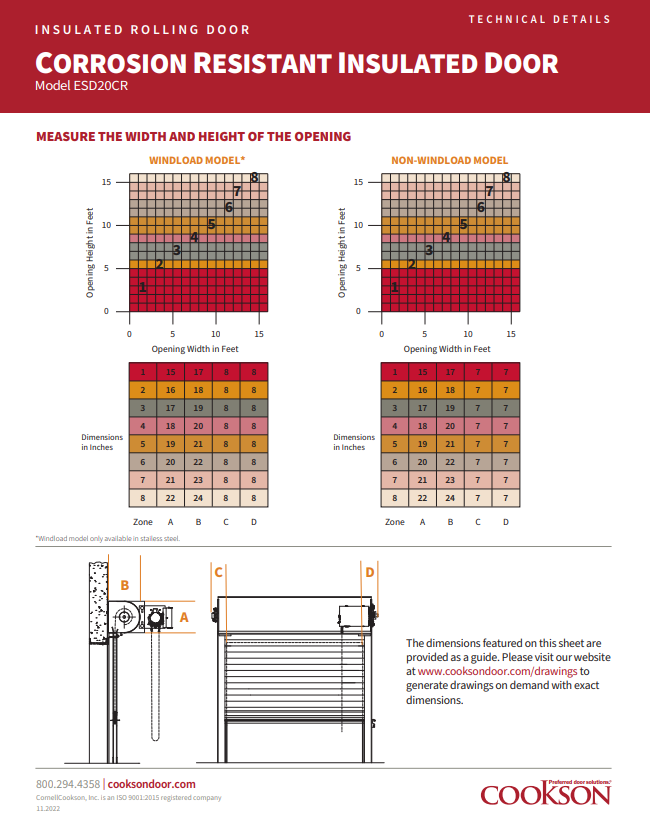

Need to see clearances and mounting details? Enter your opening dimensions into our Drawing Generator, and get custom generated drawings of your door with all the details.

Corrosion Resistant Service & Insulated Doors Drawing Generator